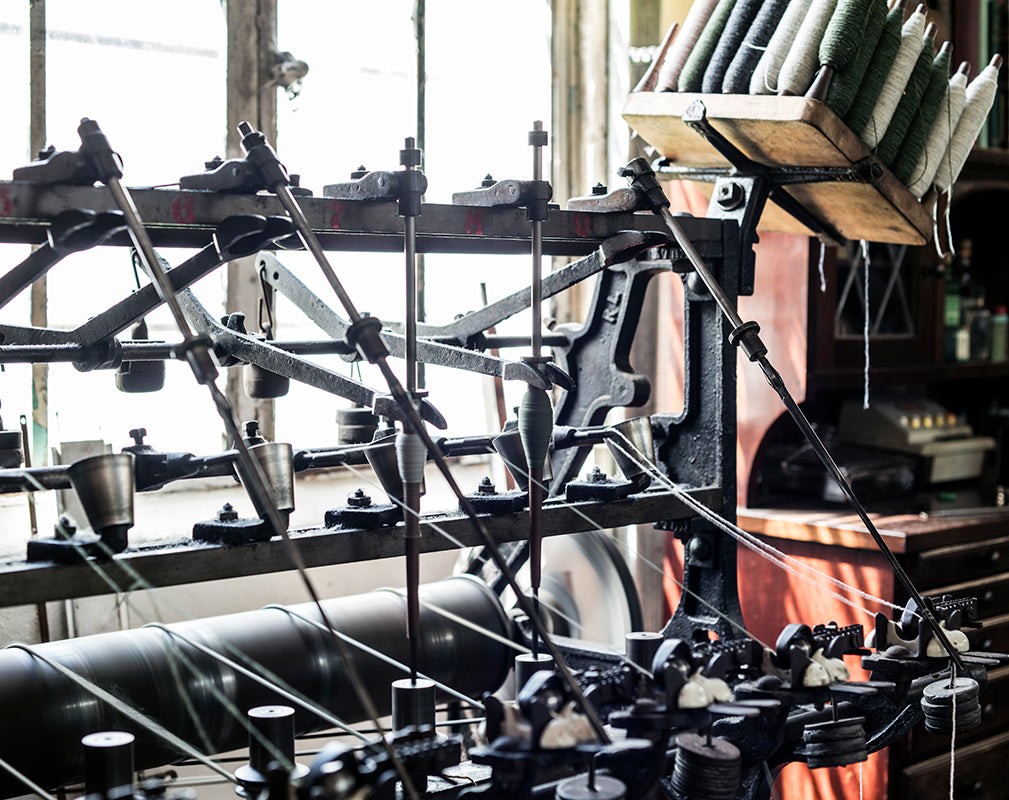

When Daniel Harris was inspired to rescue a rusting Victorian loom from an old barn in rural Wales, he had no previous weaving experience. Entirely self-taught, Daniel has individually restored a number of original shuttle looms and over the last five years, he has established a successful micro-mill on the outskirts of London.

The London Cloth Company produces over 60 different types of indigo cloth and an extensive array of fine British wool tweeds as well as taking custom orders.

Entirely self taught in his craft, owner Daniel was inspired to rescue a rusting Victorian loom from a barn in rural Wales.

With no previous weaving experience, Daniel has individually restored a number of original shuttle looms. The London Cloth Company produces over 60 different types of indigo cloth and fine British wool tweeds. Preparing the warp can take anything from 3 hours to 2 days. The looms at The London Cloth Company date from 1870 to 1974.

Photography by Oliver Perrott